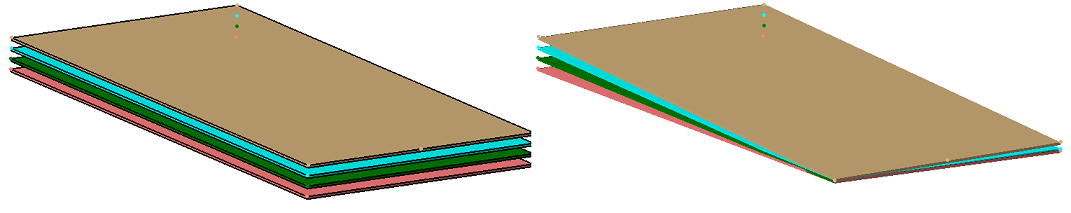

In many situations more than two parts need to be joined at the same locations.

The following procedure is recommended when joining multiple parts :

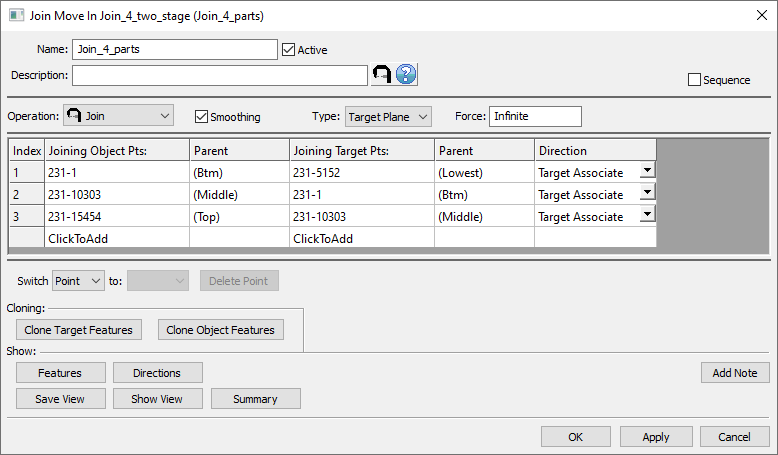

1. Fully constrain each part prior to joining.

2. Use the same point for joining with adjacent parts.

3. Use Sequence in the join move - without it the calculation cannot be performed correctly.

4. It is recommended to have zero distance between the ASET and modeling point linked to it. Otherwise a 'lever effect' can be created and the parts deformation may be incorrect.

Regarding the application of join moves, we recommend:

1. Perform all welds/joins for one assembly either in FEA or in 3DCS.

2. Whenever possible have the 3DCS points at the same location as the linked node.

3. Use the same point for multiple parts join operation with the Sequence button activated (easier that creating individual join moves).