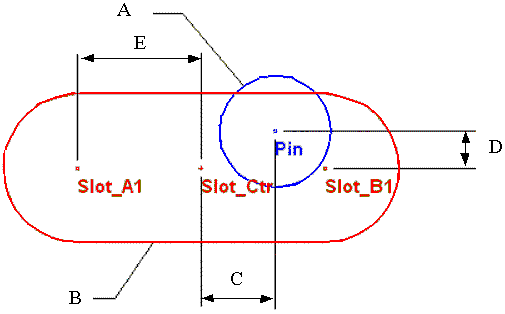

Pin to Slot Clearance Measurement

Objective 1: To measure the pin to slot clearance (or lack of) in the major axis (slot length) direction.

Objective 2: To measure the pin to slot clearance (or lack of) in the minor axis (slot width) direction.

Objective 3: To find the percentage of builds with interference in either the minor axis

direction, major axis direction, or both directions.

Description of part measurements:

A: Radius measurement on the pin

Meas: Circle Diameter

Type: Circle Diameter

Scale: -0.5

B: Radius measurement on the slot

Meas: Circle Diameter

Type: Circle Diameter

Scale: 0.5

C1: Slot center to pin center distance in major axis direction

Meas: Point Distance

Type: Pt-Pt

Scale: 1.0

Dir: + major axis direction

C2: Slot center to pin center distance in opposite major axis direction

Meas: Point Distance

Type: Pt-Pt

Scale: 1.0

Dir: - major axis direction

D1: Slot center to pin center distance in minor axis direction

Meas: Point Distance

Type: Pt-Pt

Scale: 1.0

Dir: + minor axis direction

D2: Slot center to pin center distance in opposite minor axis direction

Meas: Point Distance

Type: Pt-Pt

Scale: 1.0

Dir: - minor axis direction

E: Half of slot flat length

Meas: Point Distance

Type: Pt-Pt

Scale: 1.0

Dir: Make sure output is always positive

Description of calculation measurements

F: Negative pin center to slot center in major axis distance

Meas: Combination

Type: Min Meas

Adding List:

C1, C2

G: Negative pin center to slot center in minor axis distance

Meas: Combination

Type: Min Meas

Adding List:

D1, D2

H: Objective 1

Meas: Combination

Type: Linear

Adding List:

A, B, E, F

Design Limits:

True SL (not relative), LSL = 0, USL = 100 (so you can't have "too much" clearance)

I: Objective 2

Meas: Combination

Type: Linear

Adding List:

A, B, G

Design Limits:

True SL (not relative), LSL = 0, USL = 100 (so you can't have "too much" clearance)

J: Objective 3

Meas: Combination

Type: In-Spec

Adding List:

H, I

Spec Limits:

Absolute SL (not relative), LSL = 1.9, USL = 2.1

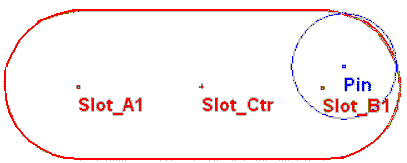

This measurement technique breaks down when the pin is "in the corners" of the slot (see above). In these cases, the condition passes both major and minor axis clearance criteria, but unless the slot is squared off, the pin will not fit. This is a small enough error percentage as to not be of concern unless the pin size is very small relative to the diameter of the slot.

Once the measurements are working correctly, the "As Output" box may be un-checked for measurements A through G.