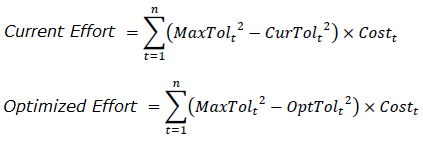

Total Current and Optimized Cost for each tolerance has a logarithmic relationship to the tolerance value. The following are equations defining how each cost is calculated.

Where MaxTol = Max Possible Range CurTol = Current Range Cost = Cost Factor t = a tolerance in the model n = total number of tolerances in the model

As a tolerance is held tighter it costs more. However, as the Current Range or Optimized Range tolerance value approaches the Max Possible Range allowed, the tolerance is relaxed and becomes cheaper. Note these equations are based on the constants. If the Current Range equals the Max Possible Range, the tolerance is "free." If a Max Possible Range constant is changed, the costs will change. The cost represents the incremental cost and, thus, the baseline is changed.

|

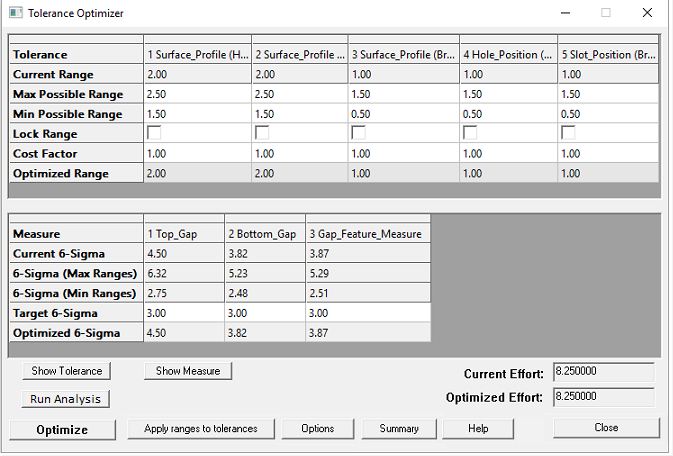

Tolerance inputs and optimized values:

•Tolerance: Name of the tolerance - all active tolerances in the model will be displayed in this top row.

•Current Range: The current tolerance value of the model. This field is not editable.

•Max Possible Range, Min Possible Range: Allow the user to define the range that tolerances can fall between in order to be optimized. A range for each tolerance that is to be optimized must be defined. The Min/Max tolerance range is by default +/- 0.5 from the current tolerance range (Current Range). For example if the a surface tolerance in the model is 4mm the defaulted Max and Min tolerance in the optimizer will be 4.5mm and 3.5mm, respectively.

The default for these two inputs can be set under the Options.

•Locked Range: Check box allowing the user to lock the current tolerance and not optimize the tolerance range.

•Cost Factor: Cost can be either arbitrary or the actual cost of adjusting the given tolerance (cost per unit change). The cost is effectively the importance or influence of that particular tolerance. Observe the cost values are defaulted to 1 cost units per tolerance unit. The Optimizer accounts for each tolerance with the same importance since the costs are defaulted to the same value.

•Optimized Range: Displays the tolerance value after optimization.

Measures inputs and optimized values:

•Measure: Name of the measurement - - all active tolerances in the model will be displayed in this row.

•Current 6-Sigma: The current measurement value calculated with Geo Factor Analysis (see Run Analysis command).

•6-Sigma (Max Ranges), 6-Sigma (Min Ranges): The highest/lowest possible measurement range, calculated with the maximum or minimum value of each tolerance.

•Target 6-Sigma: The desired variation for the particular measurement.

•Optimized 6-Sigma: The measurement value after optimization occurs (optimized measure).

Display and update commands:

•Show Tolerance: Shows where the selected tolerance in the matrix is in the Graph window.

•Show Measure: Shows the contributing points/features involved in the selected measurement in the Graph window.

•Run Analysis: Will read the inputs from the model and overwrite the current data shown in the matrix.

Optimization command and results:

•Optimize: Will optimize tolerances to achieve best quality at a minimum cost.

•Current Effort: The arbitrary or actual cost of the entire model based on Current Range, Max Possible Range, and Cost Factor values. The Current Effort does not take into account distribution types, different Sigma values of the tolerance, truncation, and number of features.

•Optimized Effort: The arbitrary or actual cost of the entire model based on Optimized Range, Max Possible Range, and Cost Factor values. The Optimized Effort does not take into account distribution types, different Sigma values of the tolerance, truncation, and number of features.

•Apply ranges to tolerances: Pushes the altered tolerances back into the current 3DCS model.

•Summary: Exports the current cost optimized matrix to Notepad.

•Close: Closes the optimizer.

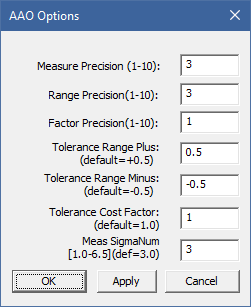

Options: Opens a dialog box that allows you to specify certain parameters:

Options: Opens a dialog box that allows you to specify certain parameters:

▪Measure Precision ▪Range Precision ▪Factor Precision ▪Tolerance Range Plus (Default = +0.5): Changes the Max Possible Range of all tolerances. ▪Tolerance Range Minus (Default = -0.5): Changes the Min Possible Range of all tolerances. ▪Tolerance Cost Factor (Default = 1.0): Sets the default value for the Cost Factor field for each tolerance. This value can be changed for each Tolerance. ▪Measure Sigma Number [1.0 - 6.5] (Default = 3.0) |

|---|

|

Note:•Floats and Size Tolerances will initially be locked when first running Tolerance Optimizer •In the Tolerance Optimizer, reducing the Hole/Pin or Slot/Pin down to 0, the Size tolerance will still affect the floats. When the float clearance is reduced to 0, any size tolerance will change both the hole and pin to their LMC sizes, giving floats a clearance. (65044). •Size is not taken into account during tolerance optimization. Therefore, if size is in the list, AAO will always Optimize to the Largest Size. The hole/pin float column is the LMC fit value, AAO can optimize the LMC fit value. That number can be used to determine what the nominal clearance, the hole size tolerance, and pin size tolerance should be. (65054)

|