DO has been added to the AAO Toolbar. For rigid parts, DO finds the optimal 3-primary, 2-secondary, and 1-tertiary datums to locate the part to a fixture/mating part.For compliant option the goals can be separated into:1. Identify the best clamping location: For a fixed number of clamps (selected from the Candidates), DO finds the optimal clamp locations to clamp the part to its fixture/mating part. To achieve this, DO loads FEA data, applies sets of clamps, applies gravity, then measures CAD points from all features to minimize the deformation introduced by gravity. 2. Identify the optimal number of clamps: Flexible parts may need more than 3:2:1 locating scheme to pass Gage R&R; the question is - how many locators are needed? Adding more locators than necessary drives costs up with no value addded. DO reduces cost by finding the gain-cost relationship in terms of part deformation versus the number of optimal clamps. |

In this section: |

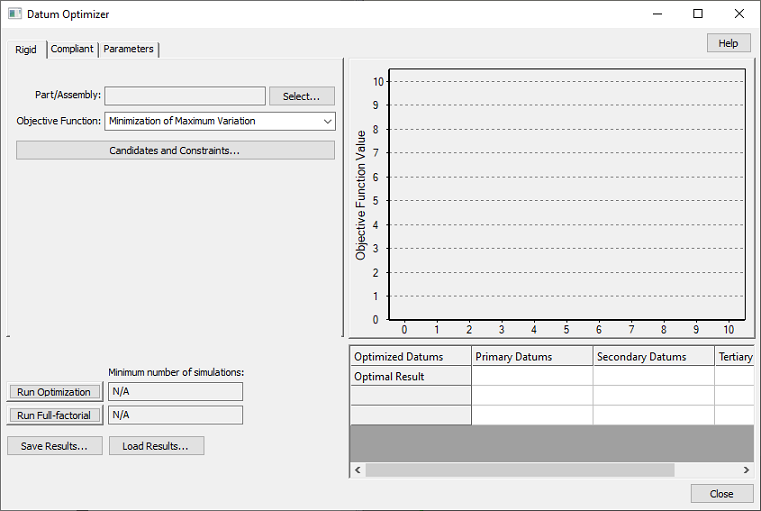

1. Rigid/Compliant/Parameters Tabs

Choose between Rigid and Compliant tabs, based on the type of study you want to perform. If Compliant then the FEA Files need to be available in the Load FEA data move (otherwise they can be selected here, manually).

2. Part/Assembly

Click the Part/Assembly button to select the part that will be optimized. The model can be in nominal build or separated position when running Datum Optimizer.

Datum Optimizer requires a parent part/assembly to complete calculations.

3. Objective Function

The Objective Function will allow selecting the type of optimization you want to perform from the drop-down menu.

3.1 For Rigid

3.1.1 Minimization of Maximum Variation - the part with optimized datums will have the smallest maximum variation range for all points on the part, meaning all 3DCS mesh points (Feature Points, Coordinate Points, and Mesh Nodes). DO rigid Deviates* 6 target points by +/- tolerance value separately, then record the min/max values for all measurements (all points). Next it will calculate the range = max - min for each measurement, then for this objective function it will choose to use the maximum variation. The Deviate here refers to deviating all points "True Distance" or "True Range".

3.1.2 Minimization of Overall Variation - the part with optimized datums will have the smallest average variation range for all points on the part. For this objective function it will choose the average variation.

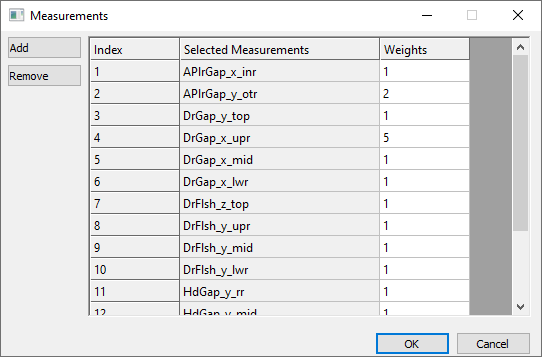

3.1.3 Minimization of Selected Measurements - the part with optimized datums will have the smallest absolute value of the selected measurements included in the optimization.

Datum Optimizer allows selecting a set of measures and assigning weights to each measure as input for the datums optimization calculation to calculate the weighted average of absolute measurement. These are measures previously created in the model. This option also refers to "True Range" over all Points.

3.2 For Compliant

3.2.1 Minimization of Maximum Deformation - the part with optimized datums will have the smallest maximum sag in the gravity direction. The calculation is based on the ASETs included in the Mass matrix.

3.2.2 Minimization of Overall Deformation - the part with optimized datums will have the smallest average sag in the gravity direction for all the ASETs included in the Mass matrix.

3.2.3 Minimization of Selected Measurements - the part with optimized datums will have the smallest absolute value of the selected measurements included in the optimization.

When selecting a new part the Candidates are eliminated and the user is prompted to select new points. If loading the part that was previously selected in the Datum Optimizer, the Candidates & Constraints dialog will remember and bring back the points that were already selected when the dialog was closed.

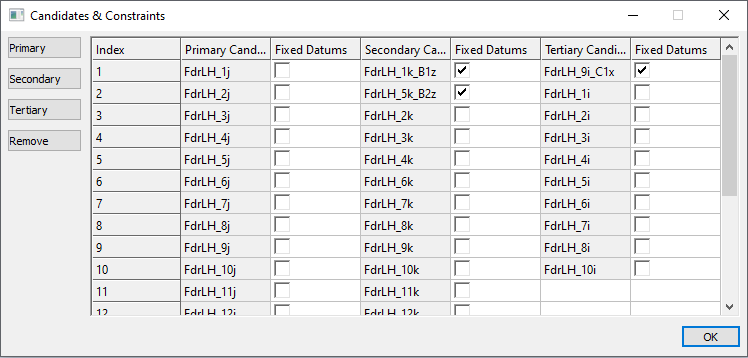

Click the Candidates and Constraints button to open the point selection dialog. These are the points that will be considered when selecting the best datums. They can be coordinate points or feature points, as long as they are linked to mesh nodes (for compliant parts only).

4.1 Use the Primary button to select the candidate object points for Primary direction.

4.2 Click the Secondary button to select the features for the secondary direction.

4.3 Click the Tertiary button to select the feature for the tertiary direction.

4.4 Use the Remove button to eliminate unwanted points.

| 4.5 Fixed Datums (for each of the three sets of candidates) are used as part of solution for every set of results, rigid or compliant. Using fixed datums can speed up the calculation by reducing the number of simulations performed during optimization. |

Notes:

oThis warning message "You cannot fix more than 3 datums in the primary direction for rigid optimization." will appear if the user is trying to fix more than 3 Candidates for Primary datums for a rigid part.(75203)

oDue to the randomness in the Algorithm used to determine the best Datums it is possible that the order in which the candidates are selected will influence the optimizer's answer.

5. For compliant only:

5.1 Select the Gravity Direction - the calculation for optimal datums uses gravity to deform the part. The gravity can be applied in any direction.

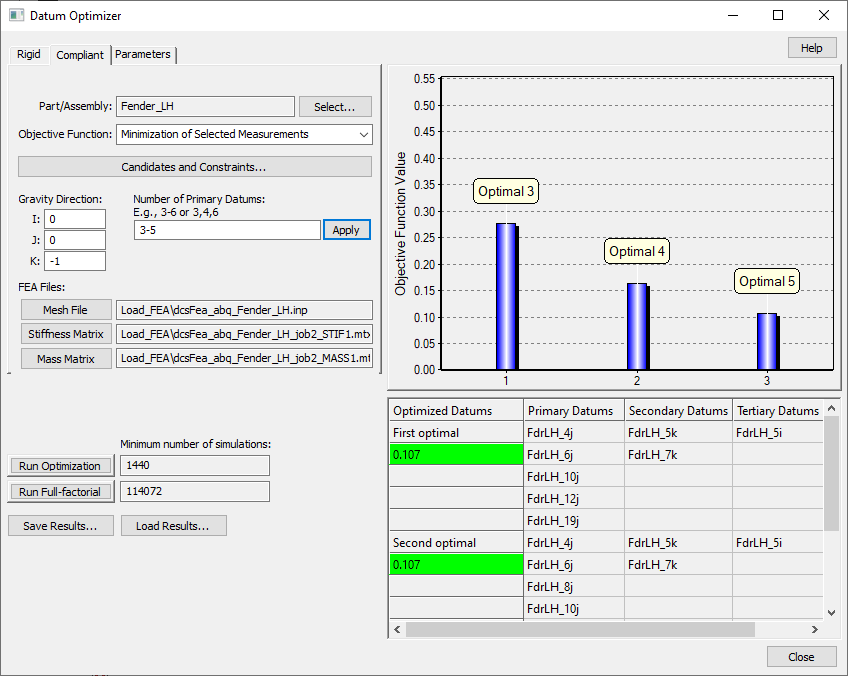

5.2 Number of Primary Datums: for a compliant part the user can generate more than 3 points as datums. A number between 3 and 6, a range, or anything in between can be selected (not limited to 6).

5.3 Make sure the FEA Files are loaded. When the part is selected under the Compliant tab, the FEA Files fields are automatically populated with the mesh file and the two matrices: mass and stiffness. If they are not, the user should check the model and make sure the files are loaded in the Load FEA Data move, or load them directly into the Datum Optimizer.

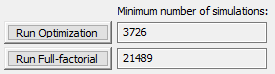

6. Start the calculation. There are two types of calculation available.

6.1 Run Optimization - using a Genetic Algorithm based optimization method to find the best combination.

***Click the Apply button if changing the number of Primary Datums to update the Minimum number of simulations.

6.2 Run Full-factorial - will simulate all possible combinations to find the best combination.

Full Factorial option is recommended unless it takes too long to perform all calculations. For large numbers of candidate locators, full factorial may be impractical due to the large number of runs required to cycle through all possible combinations. For a large number of locators, the Genetic Algorithm will require only a fraction of the simulations required by Full Factorial.

To help you choose, the Minimum number of simulations is displayed for Run Optimization and Run Full-factorial after the Candidates and Constraints are selected (Step 5).

=> If the estimated number of runs is smaller for Full Factorial, choose Run Full-factorial.

=> If the estimated number of runs is similar, choose Run Full-factorial.

=> If the estimated number of runs for Full Factorial is significantly larger than Optimization, choose Run Optimization.

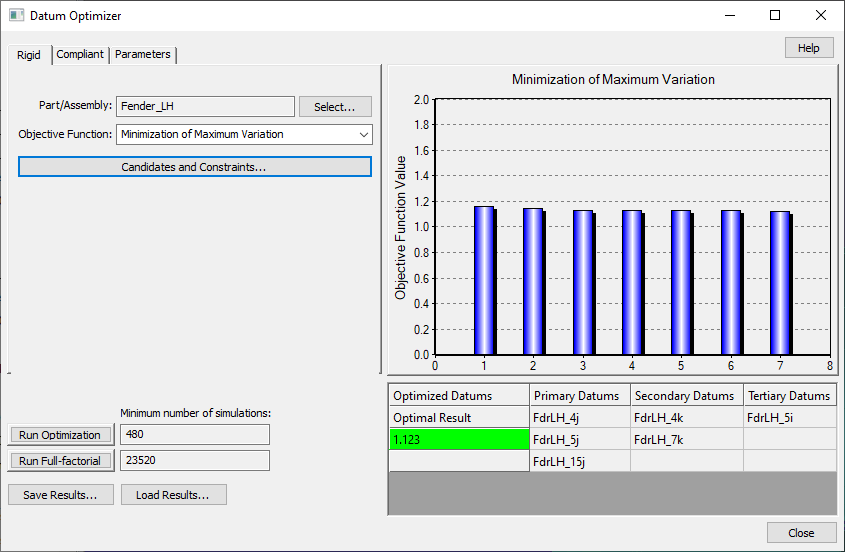

7. Rigid part analysis - one of the three types of calculation shown above can be performed.

7.1 Run Optimization results will display a reduced number of blue bars, each representing a set of three points as proposed datums, along with their Optimized Result. The best results are displayed and the selected datums are listed in the Optimized Datum box, representing the last bar. The user can select a different bar to see the result for a different set of datums option.

Note: If only one bar is shown, it means that the optimizer finds the best solution within the first try. Furthermore, if the solution does not change for 10 rounds, then optimizer stops and show the best solution.

7.2 Run Full-factorial results will display the last 1000 blue bars that result from the calculation. These bars are part of the complete results for all combinations of three points selected from the list of candidates.

8. Compliant part analysis - - one of the three types of calculation shown above can be performed.

8.1 Run Optimization results will display one blue bar for each number of datums (e.g. for a range of 3 - 5, three bars will be displayed and for a single number a single bar will be displayed). Each bar represents a set of points as proposed datums, along with their Optimized Result. The best results are displayed and the selected datums are listed in the Optimized Datum box, representing the last bar. The user can select a different bar to see the result for a different set of datums option. To keep results easy to read a reduced number of bars is displayed, with the optimized results shown as a single last bar.

8.2 Run Full-factorial results will display similar results as Run Optimization, after completing the calculation for all combinations set by the user as Number of Primary Datums.

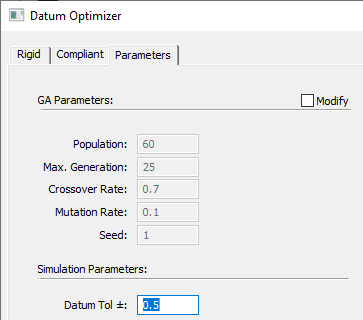

9. GA parameters - allows modifying the settings for the Genetic Algorithm Parameters for calculation improvement/optimization.

9.1 Population - the number of samples in one generation. The Population number has to be between 2 and 20000.

The population number is dynamically changed based on the number of candidates and on the number of primary datums. If the calculated value is smaller than 60, then 60 will be used as the Population number. For compliant calculation the maximum population for a range of primary datums is shown. E.g., 3-6 datums selected for Compliant Optimizer, it should show the Population number for 6 datums.

The Population size is grayed out but can be changed if user chooses to. The new number will be used for all optimization, aka, the population number will not depend on the number of candidates and the number of datums.

9.2 Max. Generation - the maximum number of generations that the optimization can evolve.

9.3 Crossover Rate - the percentage of population that will be generated from parents’ mating for next generation.

9.4 Mutation Rate - the percentage of population that will be performed gene mutation to introduce randomness.

9.5 Seed - the beginning seed of random number generator, with a value of 1 as default but it can be any integer. To achieve repeatability use the same seed number.

10. Simulation Parameters - includes settings for Rigid and Compliant optimizations.

10.1 For Rigid - allows changing the Datum Tol value - the constant deviation (±) applied on datums to generate part variation for the Rigid datums calculation.

10.2 For Compliant - the GA Parameters are grayed out by default and the optimization uses the displayed values for Population, Max. Generation, Crossover Rate, Mutation Rate, and Seed.

Population size can be changed if user chooses to by activating the Modify box. The new number will be used for all optimization, aka, the Population number will not depend on the number of candidates and the number of datums.

Validate Results

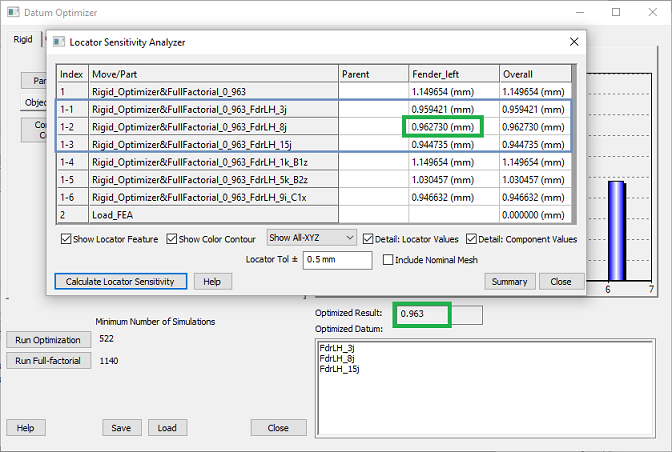

11. Rigid model DO results can be validated against the LSA results.

11.1 Activate/create the move using the same datums as the ones resulting from the DO Rigid.

11.2 Set the Locator Tol to the same value used in the DO Parameters Tab. Then activate: Show Locator Feature, Detail: Locator Values, Detail: Component Values, and select Show All-XYZ selections should be active. Do not activate Include Nominal Mesh since the CGR or HSF deviation are not considered in DO.

11.3 Calculate Locator Sensitivity: the largest Component Value for one of the three Primary Locators will match the results in the DO.

12. Compliant model DO results can be validated with compliant moves.

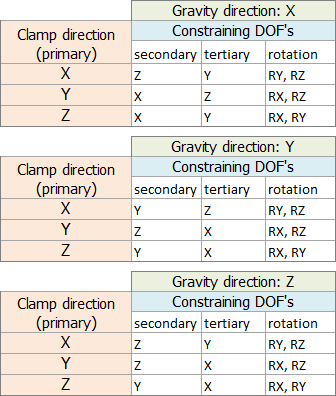

12.1 Add a LockDOF for the Secondary and Tertiary locators constraining the translations and rotations as per the following charts.

12.2 Add a Soft Clamp move using the same datums as the ones resulting from the DO Compliant.

12.2 Add a Gravity move for the part.

12.3 Add measurements for each point in the part along the same direction as the Gravity.

Save and Load Results

13. The generated results ca be saved for later as a *.dop file using the Save Results button. The *.dop files will be saved in whatever path is set in Preferences.

14. A previously saved file can be visualized in the Datum Optimizer using the Load Results button.

Help

15. The Help button will open this page to help understanding how to use this function.

Validation Messages

•Message added to run Full Factorial when Run Optimization number = 1: "Optimization takes longer than Full Factorial for one simulation, please run Full Factorial".(72619)

•Datum Optimizer cannot use dynamic points as Candidates. A warning message is prompting the user to reselect them.(74107)