This function graphically displays each assembly build that is of variation in the individual parts.

|

Procedure:

1.Click on ![]() Deviation Control, under

Deviation Control, under ![]() Deviate, to launch the Deviation Control dialog.

Deviate, to launch the Deviation Control dialog.

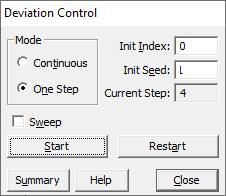

2.Specify Continuous or One Step and select Start.

Commands:

Mode: One Step or Continuous set how the 3DCS mesh and geometry will deviate.

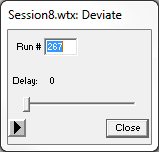

Continuous: mode will graphically display build after build of varied assemblies in the Graphics window. After selecting the Start button, the Deviate dialog appears as shown below.

•Use the Pause button to pause the deviations, and the Close button to stop the deviations and close the Deviate dialog.

•The Run # box displays the current number of the assembly deviation being performed. The default total steps number is 100,000.

•The Delay slider lets you select delay times from 0 - 25000 in different increments. The higher the number, the slower the deviation. The default delay number is 0 (the fastest).

One Step: mode displays only one assembly build in the Graphics window for every time the Start button is selected.

•Checking the Sweep box will graphically leave behind a trace of each assembly build in the Graphics window.

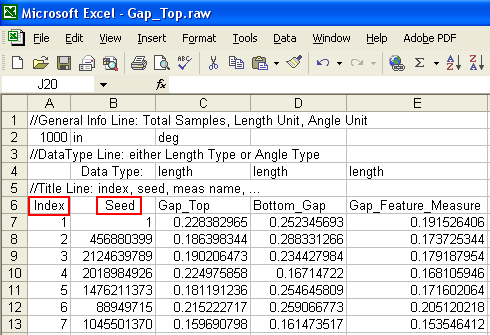

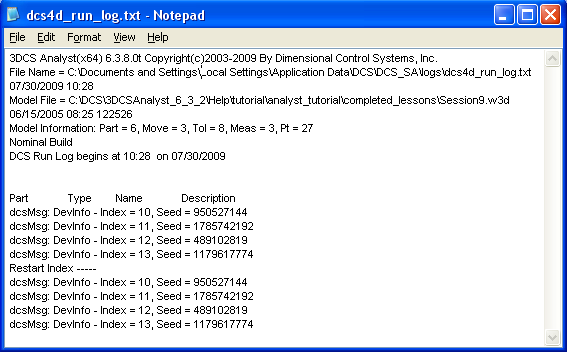

•Init Index: Allows the user to start the deviation at the specified build, based on the index number. The index number can be found in the Simulation results, saved as raw data.

•Init Seed: Allows the user to start the deviation at the specified build, based on the seed number. The seed number can be found in the Simulation results, saved as raw data.

•Restart: Press the Restart button to start the deviation at the build specified for Init Index, or Init Seed.

•Summary: Shows the build information for the One Step mode:

•Use the Close button to close the Deviate Control dialog.

Note:•The user should not modify Init Index and Init Seed, simultaneously. •Only the Restart button will take into account the modified Index or Seed number. •As an alternative to using the Deviate Control dialog, click the •Editing the Init Seed in the Deviation Control dialog will also set the Init Seed value in the Run Simulation dialog. Tips:•If a specific build has failed in the model, users can copy the Index and Seed values from the Simulation and use Deviate Control to build to this failed assembly.

|