The

See also: |

![]() How to apply a GD&T Surface Profile Measure

How to apply a GD&T Surface Profile Measure

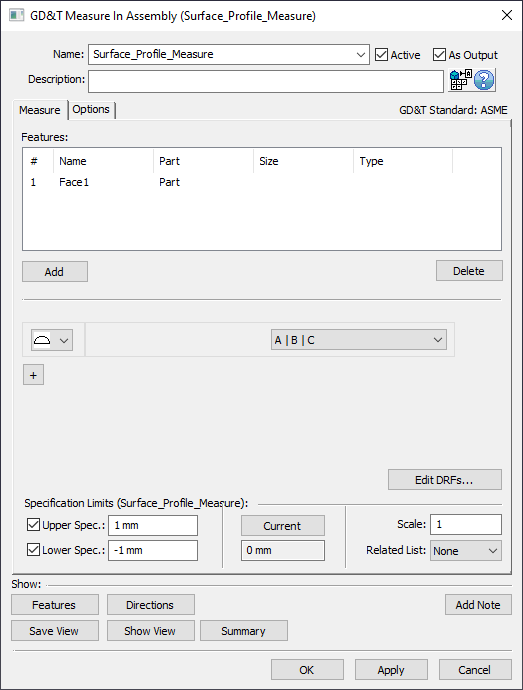

Procedure: 1.Create a new 2.Assign the new GD&T Measure a Name and Description (if desired). 3.Select [Add] and select any features from the graphics window or the Model Navigator that will be included in the Surface Profile Measure. When finished select [OK][Close] in the Pick FeatureSelect dialog. 4.Select 5.Select the desired DRF from the DRF list. Note: if needed, define the DRF by selecting [Edit DRFs...]. Also Create Datums if needed. 6.Set the Upper Spec. Limit and Lower Spec. Limit to whatever values this measure is meant to check against (typically found on Assembly level drawing). Note: Can also turn off Upper Spec. Limit and Lower Spec. Limit if desired.

|

|---|

![]() GD&T Surface Profile Measure Analysis

GD&T Surface Profile Measure Analysis

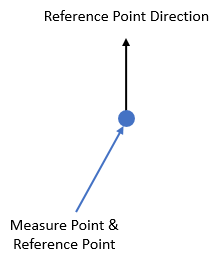

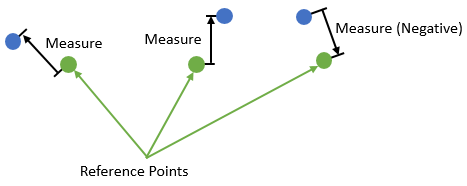

Single Point Analysis: The

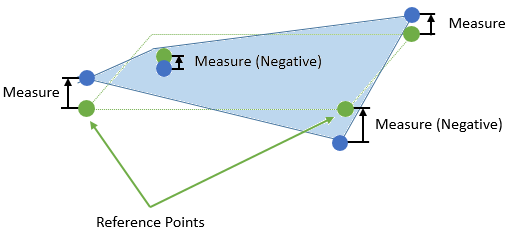

Above: At Nominal. The measure direction 3DCS will use is the direction of the Reference Point

The

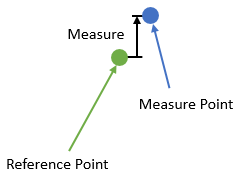

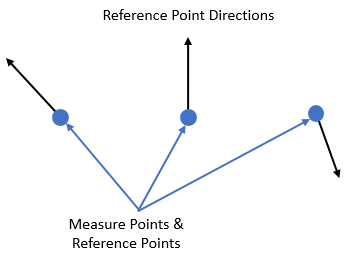

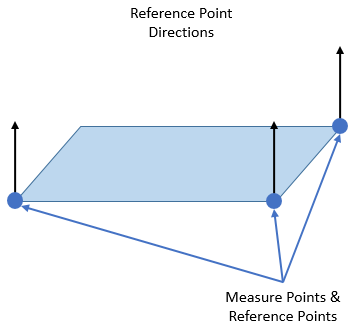

Multiple Point Analysis: When using multiple points in the Features list of the GD&T Measure dialog, the

Above: At Nominal. The measure directions 3DCS will use are the directions of the Reference Points

3DCS is not combining the three Point Distance Measures on a "per build" basis (like the Combination Measure does). Instead, 3DCS internally keeps these three measures and then only shows a single distribution at the end. The distribution shown is the one that returns the largest Recommended GD&T Value (see Recommended GD&T Value section for more details).

For an example case, we could have these three results:

In this case, Point 3 has the largest Recommended GD&T Value so for the Note: Because 3DCS is only displaying Contributor Analysis results for one of the three points, it is possible that there is a Contributor that is affecting the variation in one or more of the other two points but is not displayed in the Contributor Analysis list for the measure because it is not adding variation to the point that had the greatest Recommended GD&T Value.

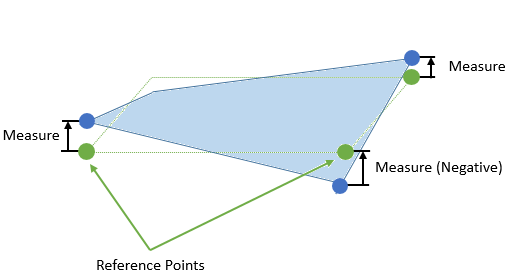

Single Feature Analysis: A Feature such as a face or curved surface can also be selected in the Features list of the GD&T Measure dialog. If a Feature has no Feature Points on it, then the

Above: At Nominal. The measure directions 3DCS will use are the directions of the Reference Points. The Measure Points are internally calculated by 3DCS to be the extreme points on a surface

For an example case, we could have these three results:

In this case, Extreme Point 2 has the largest Recommended GD&T Value so for the

Note: 3DCS does not display what these three extreme points will be for the

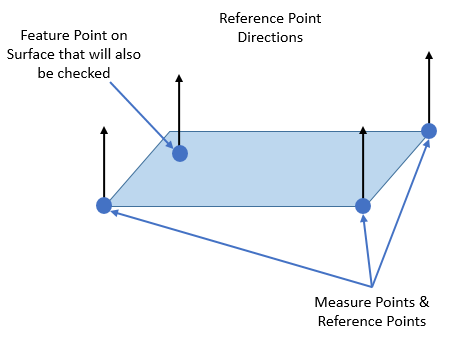

If the Feature also contains Feature Point(s) on its surface, the

Above: At Nominal. The measure directions 3DCS will use are the directions of the Reference Points. The Measure Points are internally calculated by 3DCS to be the extreme points on a surface and the single Feature Point that is on the Surface

Above: At possible deviation. The Measure Points are measured from the Reference Points along the directions of the Reference Points. The Feature Point is also included in the results

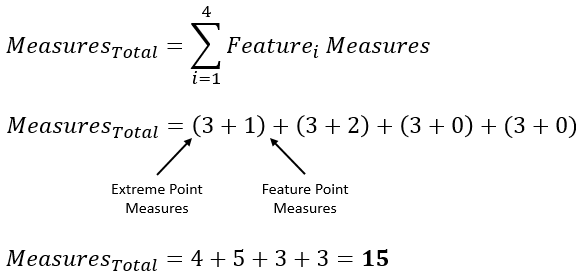

For an example case, we could have these four results:

In this case, Feature Point 1 has the largest Recommended GD&T Value so for the

The examples in this section used a nominally planar surface, but the

Multiple Feature Analysis: It is also possible to add multiple Features in the Features list of the GD&T Measure dialog. If multiple Features are selected, then the

Example 1: 4 Features Feature1: 1 Feature Point Feature2: 2 Feature Points Feature3: 0 Feature Points Feature4: 0 Feature Points

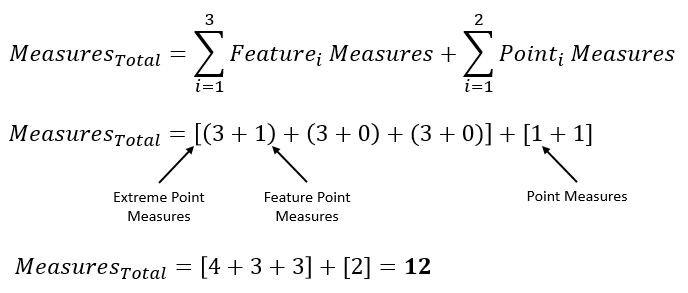

Example 2: 3 Features, 2 Points Feature1: 1 Feature Point Feature2: 0 Feature Points Feature3: 0 Feature Points

For an example case, where we have two Features selected in the Features list and neither Feature has a Feature Point, we could have these six results:

In this case, Extreme Point 2 for Feature 2 has the largest Recommended GD&T Value so for the

|

|---|