The 1. Projected on Vector (former X-Plane move (dcsMvMinDistFit)) - best-fits the object part(s) to a set of target parts along a vector set for each locating pair. Vector comes from the target points. 2. Projected on Plane (former Best Fit 2D (dcsMvLsqPlaneFit2D)) - best-fits the object part(s) to a set of target parts within a plane. 3. True Distance (former Best Fit 3D (dcsMvLsqPlaneFit3D)) - best-fits the object part(s) to a set of target parts by minimizing the sum of the squared true distances between the paired object and target features. That is, it treats each pair of locators as 6-way locators.

All these methods will constrain the part such that there may be clearance or interference at any or all locating pairs but the sum of the squares of the distances at all pairs is the minimum possible.

The Best-Fit move is programmed to iterate up to 500 times to minimize the sum of the squares of the distances between object and target for all locating pairs. The goal is to meet the Threshold which is calculated as (Search_Accuracy * 1.0e-11). For some moves the value for Search Accuracy (currently 1.0e-05) is too restrictive; increasing this value will help execute the move. Whether the Threshold is met or not, the move will be executed and the part(s) will be set to the best location possible. Search Accuracy is found under the Logic tab in the move dialog.

|

|

See Also...

|

Example Model:C:\Users\Public\Documents\DCS\3DCS_V5_8_2_0_0\3DCS CAD & Example Models\Reference Models\Moves\Best Fit move |

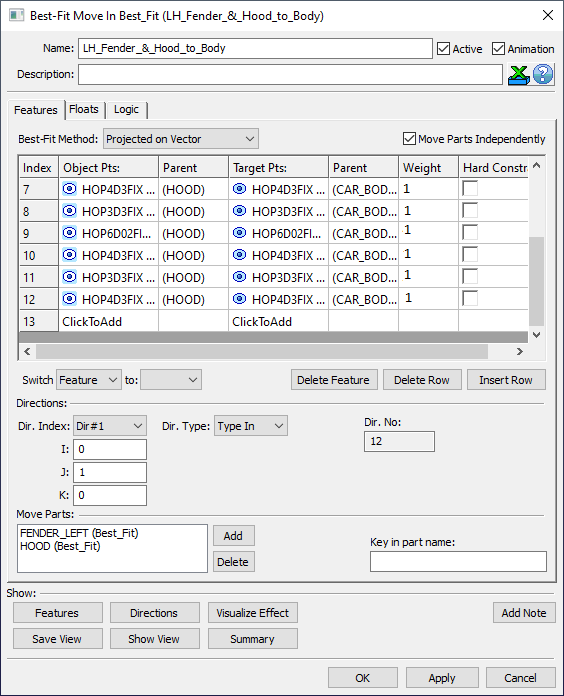

This routine will best-fit the object part(s) to a set of target parts along a vector set for each locating pair.This move will be applied in two different ways based on how the object parts should be moved.•The [Move Multiple Parts] option should be checked if there are multiple object parts that should be moved independent of each other. For this option each object part should have sufficient features listed under the Object Points list to fully constrain it. •If the [Move Multiple Parts] option is left unchecked the object parts are moved as a group. Inputs:•n object features on the same part or on different parts •n target features •The object and target features should be paired; there can be a gap or an interference at the locating pairs along the set direction. The pairs can be in any order. •n directions selected from the Target points. •At least one Move Part - the moved parts list is populated when object points are added. •Weight (Optional): The 'Weight' purpose is to give priority to some of the object/target points pair over others. The larger the weight value the more emphasis on the pair it is applied to. Weights are applied to the distance between each object/target points pair before they are squared. The distance is simply multiplied by the weight indicated by the value. Then the squared result is added to the sum of all distances. The default weight is 1.

•Hard Constraint - this setting is used to eliminate the deviation along a specific direction for a specific pair. The object point will be located onto the target plane along the target vector direction for all assemblies when the 'Hard Constraint' box is checked.

Method: The distance between each object feature and its target plane is measured. •If the object part is over-constrained, the object part will be best-fit by minimizing the sum of the squares of the distances. •If the object part is perfectly constrained, the move will act the same as a Six-Plane move. •If the object part is under-constrained, the object part will be best-fit by minimizing the sum of the squares of the distances (typically the sum will become zero) and be uncontrolled in the other directions. This is not recommended.

Floats: Floats are supported with this move. Users will need to apply the correct directions in the move, and two floats can be applied: •4-way float: Must have a hole and pin dedicated in the move. •2-way float: User can use a hole and pin, or a slot and pin/tab (Feature Slot or tab). •Notes: o4-Way/2-Way floats features can be added in any order in the feature lists. They must match Object/Target order. oIf no directions are applied for the Floats features, directions will be assumed based on the target plane direction. oThe floating pairs will be applied in the order in which are listed (for the active pairs), if more than two pairs for secondary direction and one pair for tertiary direction are active.

|

|---|

This routine best-fits the object part(s) to a set of target parts within a plane. It controls two translation and one rotation degrees of freedom in the plane. This move is similar to the Pattern floating fastener move except it doesn't consider feature sizes. Inputs:•n object features •n target features •The object and target features must be paired. The pairs can be in any order. •One direction is required •At least one Move Part Method: All the object and target features are projected onto a plane normal to the set direction. The distance between each projected object feature and its projected target feature is measured. The object part will be best-fit by minimizing the sum of the squares of the distances. The distance between the average of the target features and the average of the object features measured along the direction is the same before and after the move. |

|---|

This routine best-fits the object part(s) to a set of target parts by minimizing the sum of the squared true distances between the paired object and target features. That is, it treats each pair of locators as 6-way locators. Inputs:•n object features •n target features •The object and target features must be paired. The pairs can be in any order. •Directions are ignored •At least one Move Part Method: The true distance between each object feature and its target feature is measured. The object part will be best-fit by minimizing the sum of the squares of the distances. |

|---|