The purpose of

|

Inputs

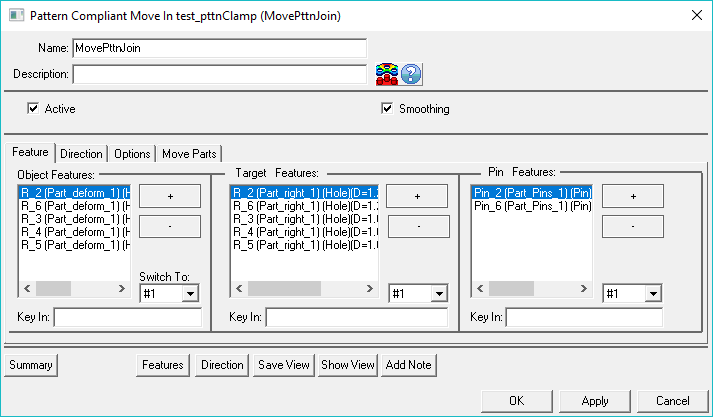

Select the ![]() Pattern Compliant icon to open the Pattern Compliant Move dialog box.

Pattern Compliant icon to open the Pattern Compliant Move dialog box.

•Name: The move name must be unique to the model.

•Description: This is an optional explanation of what the move does.

•Help: The Help button is context sensitive; it will open the Help Manual at required topic page.

•Check the box to Turn On Smoothing (only to show the deformation graphically).

Feature Tab

•Object Features: 2 to n object points with corresponding hole diameters.

•Target Features: 2 to n target points with corresponding hole diameters.

•Pin Features: 0 to n pins with corresponding pin diameters.

Direction Tab

•Directions: This is the alignment direction for the pairs of holes. The Dir Type can be toggled between Type In, Two Pt, Normal, AssocDir, PickPtDir.

![]() If AssocDir is selected, the floating direction is the direction of the first Target Feature.

If AssocDir is selected, the floating direction is the direction of the first Target Feature.

![]() If PickPtDir is selected, user can type in the point name, or select editor first then click pt on screen.

If PickPtDir is selected, user can type in the point name, or select editor first then click pt on screen.

•Align Plane: This option will translate the object part until it aligns the first object feature to the first target feature in the Pattern's direction (direction can be set with the available Dir. Type options), thus setting the primary plane of the object part(s). This way the move controls all six degrees of freedom of the object part(s).

Options Tab

•Conditional Logic: A condition can be added to this move. See Conditional Logic

•Open Increment: This is the number used to increase the temporary opening in order to find a solution.

•Iter Num: The number of times the move should perform, in order to find a solution.

Move Parts Tab

•Shows the parts that will be repositioned. Parts are automatically added based on the object points selected in the move.

Outputs

Pattern rigid will move the object points to new positions. Then the object points will be clamped or joined to that new positions.

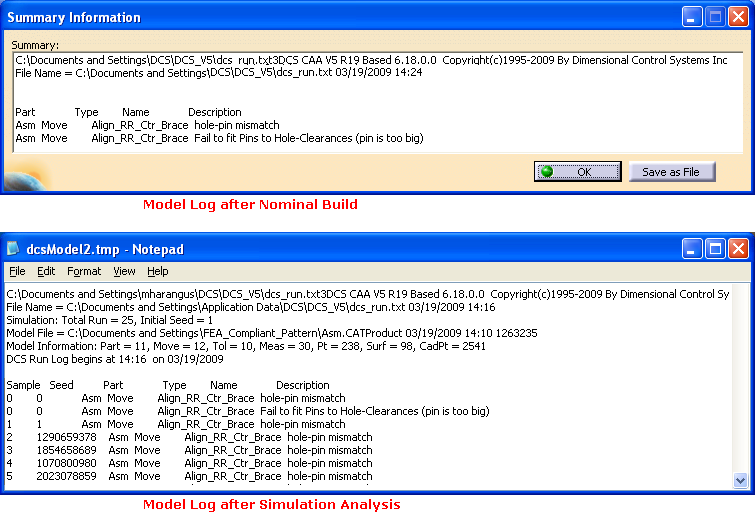

Note: If a no-build condition exists, Pattern Move will report the "no builds" during Nominal Build and Assembly.

Assumptions

•The opening between a pair of holes can never be larger than the smallest hole.

•The accuracy will only be as good as the 'Open Increment'.

•A minimum of two sets of holes is needed for this routine.

•The smaller the value used for 'Open Increment', the longer the model may run to find a max opening.

•Vector used to define the target surface will default to the vector associated with the first target point.

•The nominal object and target surfaces, in the area of the holes, are assumed to be flat and parallel.

•'x' number of pins:

o If x = n, all holes will be treated as floating fasteners

o If x = 0, the object will be adjusted so that the smallest opening will be as large as possible.

•Only holes are used (no slots).

Notes:

•The purpose of the Pattern move is to model the float when multiple hole-pin pairs are used as locators. Since no single pair acts as a locator, the Pattern move cannot calculate a nominal position. Therefore, this move is not activated in the Nominal Build, as well as the Animate functions.

•Furthermore, the Pattern move does not run through high-low-mean states in the Sensitivity Analysis because it is using conditional logic, i.e., the high and low float magnitude will depend on the effect of other tolerances. The Sensitivity Analysis will show the relative effects of variation excluding the float from the Pattern move. This exclusion does not invalidate the Sensitivity Results, but the user should be aware that the Pattern move may also be contributing to the measured variation.

•See Analysis Comparison & Assumptions.

Also See: