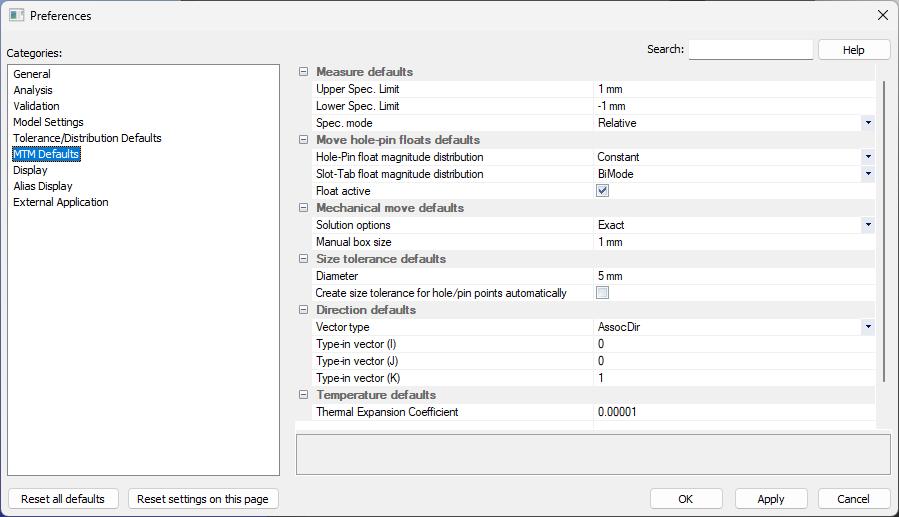

Default settings for Move, Tolerance/GD&T and Measures can be set using the MTM Default tab. The default settings will take effect in all subsequently created Moves, Tolerances/GD&T and Measures.

Within this section:

|

This allows default specification limits and measurement modes to be set. For more information on this topic, please see Specification Limits within Measurement Common Parameters.

Note: The default setting for the measurements are changed to Relative, and the Spec Limits to +\- 1mm. If these new settings do not apply for new measurements, open the Measure Defaults dialog and use the Reset All button.

Float Active: While this option is active in Preferences, any new moves created with Floats will have the floats activated automatically. While inactive, the new moves will still create the Floats but they won't be active once the move is created.

Hole/Pin Float Defaults: Constant (Rand#1); Uniform (Rand#2)

Slot/Pin Float Defaults: Uniform (Rand#1)

Click here to see all of the available Distributions

Mechanical move defaults

Users will need to have the Mechanical Modeler license to edit the Mechanical moves option. |

Solution Options: Exact: This setting will set the moves to use actual geometry to contact, if a plane or surface, or at the center of an axis. Unless an offset is applied.

Manual Box: A Manual Box can be added to a move to apply a space between the object and target features, if the assembly build process is over-constrained.

Manual box size: Default size of the Manual Box solution option for new mechanical moves.

Size Tolerance defaults: This section allows the user to set the default Circle Diameter size and creation parameters.

Diameter: Automatically set the diameter size for Coordinate Points.

Create a Size Tolerance for Hole/Pin Points Automatically: This option will control whether a Circle Size tolerance (Legacy) is created automatically for Coordinate Points on a Hole/Pin.

•When Inactive, the Circle Size Tolerance will not be shown or available in the Tolerance list, it will also set the Range and Offset to zero. Users can use either Size Tolerance (Tolerance) or Size Tolerance (GD&T).

•When Active (ON), then it shows all the Circle Size tolerances in the tree, deactivated for the ones that were created earlier when the setting was Inactive (OFF).

Direction default settings: This section will allow you to set how the initial directions are defined, when creating a new Move, Tolerance or Measure.

For more information about directions, please see Vector Direction.

Thermal Expansion Coefficient - describes how the size of an object changes with a change in temperature. Specifically, it measures the fractional change in size per degree change in temperature at a constant pressure, such that lower coefficients describe lower propensity for change in size.